Speed motor refers to the integration of the reducer and the motor (motor). It is usually also called a gear reduction motor or a gear motor. Produced by the manufacturer after assembly and assembly.

The working principle is to reduce the speed by passing the power of the motor through the gear (or worm gear) reducer, thereby increasing the output torque of the reducer motor to meet the needs of mechanical equipment. This power transmission equipment has a core that cannot be ignored-the function of "increasing power and reducing speed". It uses the gears (or worm gears) at all levels to achieve the purpose of speed reduction. The reducer is composed of gear pairs at all levels.

The most commonly used types of gear motors are: coaxial helical gear reduction motors; parallel shaft-helical gear reduction motors; bevel gear-helical gear reduction motors; bevel gear-worm gear reduction motors.

The gear motor has three main functions:

I. Decrease the speed: Pass the speed of the motor through the reduction gear box to achieve the required speed, which is often called the output speed; < p>

Increase the torque: Under the same power condition, the gear reduction motor with slower output speed will have greater torque, and vice versa;

Third, change the transmission direction: for example, a bevel gear motor can transmit torque 90 degrees vertically.

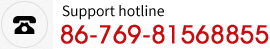

Phone

86-769-81568855

86-769-81568858